Before we discuss how to prepare for a load line survey onboard, let us first understand how many type of load line surveys are there and what all things are inspected in such type of load line surveys.

Types of Load Line Survey

- Initial Survey

Before a ship is put into service, a complete inspection of the structure and equipment is carried out to ensure that ship complies with the requirements of the Load line Convention with respect to arrangements, material, and scantling.

- Periodical Survey

It is carried out at 5-year interval or less to ensure that the structure, equipment, arrangement, materials and scantlings comply with the requirements of the load line convention.

- Annual Survey

Carried out at three months either way of the annual anniversary date of the load line certificate. An annual inspection is carried out to ensure that no altercations have been made to the hull or superstructure which may affect the calculations to determine the position of load lines and that fittings and appliances have been maintained in an effective condition for:

- Protection of openings.

- Guard rails.

- Freeing ports.

- Means of access to accommodation.

Now, as we know what are the different types of load line surveys and what all things are inspected in these surveys. Let us now focus on how to prepare for a load line survey on board.

Let us have a look at the items that are normally checked during a load line survey on board, hence we should prepare accordingly.

Following Items Will Be Checked During A Load Line Survey

- Visual examination of Load line certificate and all other certificates to ensure that they are valid and have been endorsed.

- General inspection to ensure that no modifications are carried out which affect the Condition of the Assignment of Load line for the vessel.

- An inspection of the strength, in general, will be carried out. One or two holds may be internally inspected to gauge the strength of framing, etc.

- The stability booklet will be checked. Whether all information necessary for safely loading and ballasting the ship has been provided.

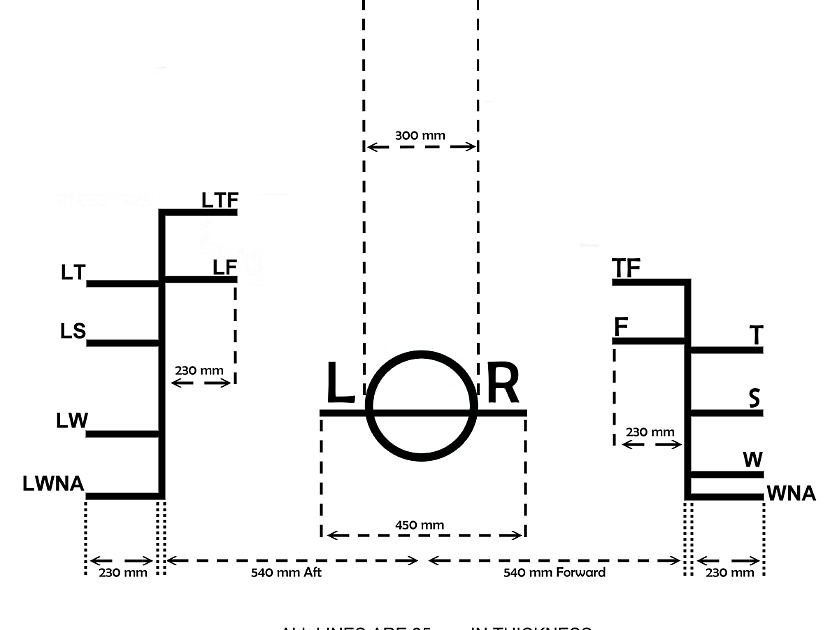

- The position and marking of load lines on both sides will be checked to be as per the load line certificate.

- Hatch covers should be watertight. All fittings should be in good condition.

- Ventilators should be capable of being closed. Packing to be in good condition.

- Flaps of the ventilators, doors, booby hatches, etc should be marked with “Open” and “Shut”.

- Watertight doors’ packing must be in good condition.

- Air pipes should be capable of being shut easily, packing should be in good condition.

- Machinery space openings should be capable of being shut.

- Portholes should be weathertight. Portholes below the main deck should be fitted with deadlights and capable of being closed watertight.

- All inlet and outlet valves are to be checked that they are watertight.

- A lifeline should be provided on the deck for use in rough weather. Guard rails and Bulwarks should be fitted. Catwalks should be provided on the tankers.

- Freeing ports provided on the bulwarks should not be obscured.

- Spurling pipe opening must be capable of being closed.

- Eductor system for chain locker and forepeak store must be working.

So, as we know what all items will be checked during a load line survey, we can prepare accordingly by making sure that all the items listed above are duly checked and are in good condition.