There has been a recent incident where a 2nd office fell from the Jacobs ladder whilst checking the out board draft and unfortunately lost his life, leaving behind a wife and 2 children.

This is a preventable accident and with the use of a manometer by ships personal

Operating standards can fluctuate from one ship to the next, and ship list management is not an exception. I have worked with officers who have had no practical means of accurately measuring their ship’s list and have accepted a 20cm list as being upright when conducting a draught survey. Being able to manage and evaluate list accurately is paramount to safe loading practices and can assist greatly in the accuracy of draught survey calculations.

A manometer is one of the cheapest and most effective means of managing and measuring list. Essentially a manometer is a hose filled with water that runs along the beam of a ship, where the difference in the water level between the port and starboard side corresponds to the list. A manometer can measure list to less than a centimeter and depending on geographical and environmental factors, can provide greater accuracy than actually reading the outboard draught marks.

At its very basic form, a manometer can be set up with a hose, a ruler and a marker.

Hose Reel

A garden hose reel makes it easy to store and unpack a manometer hose. It also makes it easy to move the hose to and from your vehicle and on and off a ship. It is important to get the right size reel to accommodate the length of hose that you need. The length of hose will be dependent on the size of the ship, for example, 50 meters for a Capesize, 35m for a Panamax.

Valves

Valves on the ends of a manometer hose ensure that the water is contained when the hose is packed up. The hose can be filled with water and the valves closed to avoid bubbles residing within the hose. Closing the valves will avoid evaporation of the water in the hose when the manometer is not being used. Also, closing the valves when the ship is listing when cargo is being loaded into or discharged from the wings of a hold will avoid water flowing out of the hose.

It is a common ‘beginner’s’ mistake to forget to open the valves when monitoring and measuring the list. Closed valves will of course, stop the flow of the water within the hose, which will likely provide a false indication of the list.

Hose

8mm – 10mm clear polyethylene hose is practical for the requirements of the job. The size allows for the water to flow freely, therefore being responsive to the change in the list. The size also allows for water to be added to the hose without air lock restrictions and is practical in the fact that it is not too heavy to be carried around when full of water.

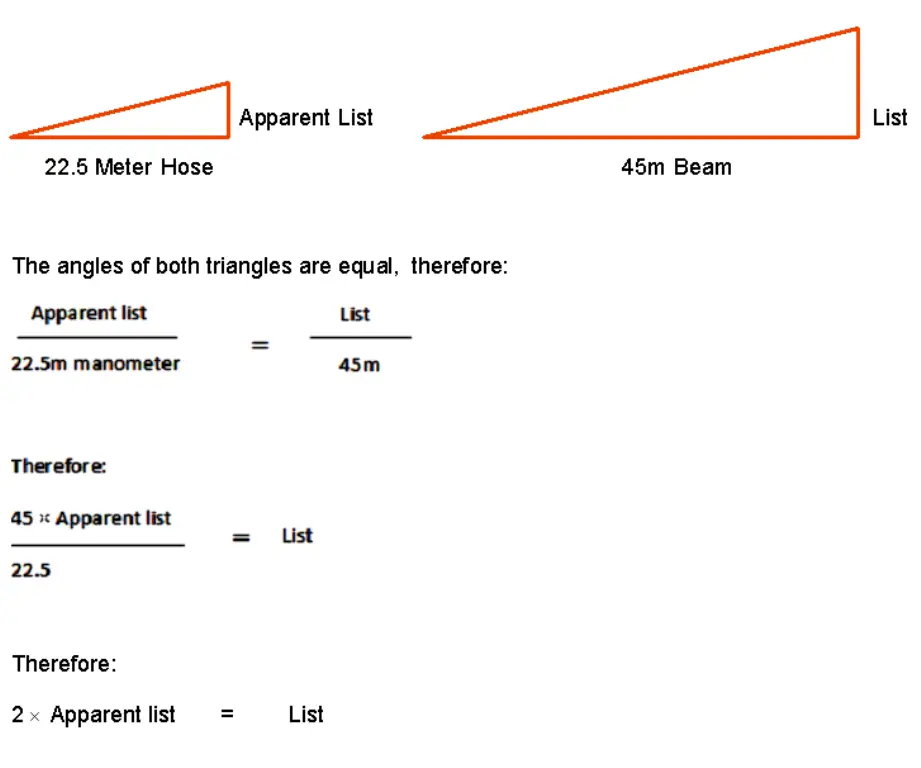

The length of the hose needed is dependent on the beam of the ship. It is best to have the hose cover the entire beam of the ship with a few meters to allow for obstacles along the deck and length to run up the rail. It is still possible however, to set up a manometer if the length of hose does not cover the beam of a ship. This can be explained by the diagrams below, using a 45m beam ship as an example, where a 22.5 meter length of hose is used.

In this case, if the difference between the port and starboard sides of the 22.5m manometer is 5cm, then the actual list of the ship is 10cm.

The condition of the hose must be checked every time the manometer is used to ensure accurate results. Inaccuracies can result from leaks, kinks and air bubbles. A kinked hose will restrict the flow of the water and air bubbles can impede the even flow of the water as the ship lists.

Water Colouring

The benefits of colouring the water inside the hose is that the water level against the measuring device is made much easier to read and that bubbles within the hose are much more noticeable. The easiest way to fill a hose with coloured water is to first fill a bucket mixing the colouring to the water and then syphon the water through the hose by gravity.

Sunflower oil is a great substitute for water when operating in freezing temperatures as its freezing point is -17 degrees Celsius.

These two pictures demonstrate the difference between clear and coloured water when determining the water level.

Measuring the Water Level

The water level of a manometer can be measured with a ruler, tape measure or makeshift measuring boards. A carpenter’s ruler folds from 25cm out to 1 meter. This makes it compactable, light weight and easy to carry in a bag. A carpenter’s ruler is easy to read with clear markings and can be taped easily to the ship’s rail. If a ruler is not available, the same results can be achieved by marking measurements on the ship’s rails with a black marker and a tape measure or sounding tape. It is important to ensure that both the port and starboard sides are of equal vertical distance from the keel of the ship. The average between the port and starboard level will be the point at which the ship is upright. It is important to know that this average can change when the temperate changes as the hose will expand and contract.

Benefits

Manometers add to the safe working practices of surveyors and seafarers and provide safety for the ship itself.

On the 10th of July 2015, a crew member from the M.V. Hyundai Dangjin died when he fell from the ladder whilst reading the outboard draught marks. Manometers are proven tools for accurately determining the outboard draught marks and negate the need for climbing down the side of a ship to read the marks whilst the ship is alongside a wharf.

The accuracy of manometers ensures that ships can be made upright after completion of loading. This is an important safety factor for ships loading to maximum sailing draughts, as a ship that is listing after completion of loading will end up exceeding the maximum sailing draught on either to port or starboard side.

The efficiency and accuracy of both the trimming and draught survey can be greatly improved with the use of a manometer. Efficiency and accuracy of trimming comes down to how well the ship’s crew, terminal, loader operator, PIC and surveyor works together as a team. With the use of a manometer and trained crew, the crew can continuously and safely convey the ship’s list to the loader operator, PIC and surveyor. This is an important factor during trimming to ensure that the ship ends up loading to the right draughts and finishes in an upright condition.