Onboard ship for the production of fresh water for drinking purpose and other sanitary uses fresh water generator is provided

There are 4 types of freshwater generator :

1.Submerged type: also known as a single-effect boiling evaporator. It was one of the first types of f.w.g. used in olden days. Was very bulky and for cleaning required lot of de-scaling in the form of physical work. Required careful attention when in use otherwise caused the sea-water to be primed to the distill water side.

It consists of a vertical cylindrical shell. The lower half is the water space which has steam heated copper coils. Seawater is pumped into the evaporator, where it boils and changes into vapours. These vapours then rise and pass through a baffle plate, where water particles are scrubbed off. Then through a vapour valve at the top, it passes into the condenser where it is condensed. As the seawater boils, it leaves behind salt particles and thus the density of water in the evaporator increases continuously. This is taken care of by using a brine ejector.

2.Alfa Laval type: consists of two sections: evaporator section and the condenser section. Seawater is pumped into the evaporator section in a controlled manner through an orifice. In the evaporator section, a vacuum is created by ejecting air, this helps in reducing the boiling point of seawater, water now boils at about 60-75 deg c. Main engine jacket cooling water which is at 60-75 deg c is passed through the heat exchanger in the evaporator section. Seawater boils off and the brine which is left behind is pumped out through the brine water ejector. The water vapour formed in the evaporator section passes through a demister to the condenser section, where it condenses into fresh water. Seawater is used to condense the water vapour. This is pumped into storage tanks via a salinometer, if the salinity increases about more than 10ppm, the water is dumped into the bilges in order to avoid contamination of the water already stored in the distilled water tanks.

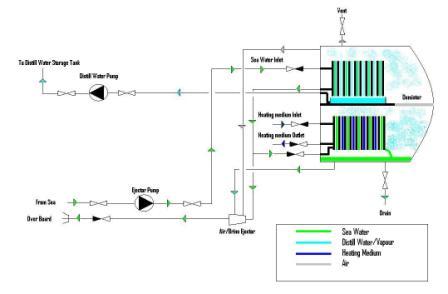

3.Flash type: in this type of f.w.g. flash process is used to evaporate the sea water. Flash process is when heated sea water is led into a chamber which there is sub-atmospheric pressure, the water instantly flashes into steam. Air is extracted using air extractor. Seawater is heated and passed into a chamber which is maintained at a pressure lower than atmospheric pressure. The sea water instantly flashes away into steam. It then passes through demister pads and condenses due to the presence of cool sea water line. The brine water so formed in the flash section is discharged using the brine pump. The distilled water is discharged into the tanks by the distillate pump.

4.Reverse osmosis: osmosis is the process when water passes from one side of the semi-permeable membrane to salt or solution on the other side. This happens due to osmotic pressure. Reverse osmosis is the process, which makes use of this process. Seawater on one side of the membrane is pressurized by a pump and forced against a semi-permeable membrane. Pure water passes through but not salt. For the production of a large amount of pure water, the membrane area must be large and tough enough to withstand this pressure. The material used is polyamide sheets made into spirally wound cartridges, a set of tubes installed in series improves the purity of water. One problem is that salt particles get accumulated and gradually block the membrane. The design of the cartridge is such that seawater feed passes through the spiral wingdings over the membrane sheets, with a washing action, assisting the surfaces to keep clear of deposits.

Pre-treatment and post-treatment for reverse osmosis plant.

Pre-treatment

- A sediment filter to trap particles including rust and calcium carbonate.

- Optionally a second sediment filter with smaller pores.

- An activated carbon filter to trap organic chemicals, and chlorine which will attack and degrade r.o. membranes

Post-treatment

- A second carbon filter to capture those chemicals not removed by RO.

- An ultraviolet lamp or ozone treatment for disinfecting any microbes that may escape filtering through the RO membranes.

Causes for a drop in production capacity of the plant.

- Drop in a vacuum which results in higher boiling temperature. This may be due to a) faulty air ejector system, b) leakages in shell mountings – pressure gauge systems, water level gauge glass connection or at gaskets.

- Dirty / scaled condenser or evaporator tubes leading to insufficient heat transfer.

- Insufficient seawater feed due to the chocked orifice or low seawater pump pressure.

- Diesel engine jacket cooling freshwater temperature falling below the normal range.

- High seawater temp. resulting in less condensation and less production of fresh water.

If chemicals harmful to humans have been used for the treatment of diesel engine cooling water, the water should not be used for drinking purpose. This is because of accidental intermixing due to leakages. Also if water is within certain coastal limits, the seawater may contain harmful effluents from industrial zone and none of the sterilization methods will give protection. The distilled water produced onboard does not contain scale-forming salts and is thus suitable for boilers and drinking. The fresh water taken from shore may contain scale-forming salts and thus should be avoided for use in boilers.

Hello there, just became aware of your blog through Google,

and found that it’s truly informative.I’ll be grateful if you continue this in future.

Lots of people will be benefited from your writing.

Cheers!