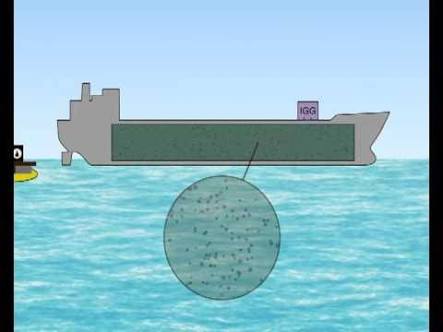

- Clean ballast is taken at sea after thoroughly cleaning the dedicated cargo tanks.

- Before taking in clean ballast the slop tanks which contain the tank washings have to be carefully decanted. That is using the ODME in compliance with MARPOL regulations, only the clean water which would have settled to the bottom is pumped out and the oily water mixture and oil at the top is retained on board. This will provide enough space for water used for flushing prior to ballasting the CBT’s.

- Although the lines would have been flushed when washing the clean ballast tanks second flushing is necessary to be confident that no oil remains in the line which may find its way into the CBTs.

- To effectively flush the cargo piping the following procedure may be followed:

- Set the lines and valves to fill the nominated clean ballast tanks. Do not open the valves of the ballast tanks.

- Fill the line with clean seawater and allow it to settle for at least 30 minutes. On ships fitted with tank cleaning heater, if the water is heated this will produce better results. This will allow any trapped oil or light clingage to float off.

- The flushing to be done using the pump run at moderate speed.

- First, thoroughly flush the line to the slop tank, then any branch lines leading to cargo tanks that have not been washed.

- Finally the risers and manifold lines.

- Flushing should be so thorough that when the lines are used for filling clean ballast there should be no trace of oil – then this can be flushed overboard if the ship is not in a designated special area.

- If the ship is in a special area where discharge is prohibited by MARPOL then the line flushing should be taken into the slop tank – allowed to decant and only clean water permitted to be pumped overboard through the ODME.

- Clean ballast tanks should then be filled in when the ship is in clean water (not in rivers or canals).

- When filling with clean ballast the tanks should be frequently and carefully inspected for any trace of oil.

- If any trace of oil is found – the ballasting should be stopped, the tanks should be stripped to the slop tank – if need be washed again and then start filling clean ballast after flushing the lines.

- PLEASE NOTE NOT EVEN A SHEEN OF OIL SHOULD BE NOTICED WHEN PUMPING OUT THIS CLEAN BALLAST WHEN IN PORT. THESE PRECAUTIONS MUST BE TAKEN TO AVOID ANY POSSIBLE DELAY TO THE SHIP IN THE LOAD PORT OR THE POSSIBILITY OF A POLLUTION INCIDENT.

- Ballast tanks must be completely filled to the deck level to reduce the amount of structure exposed to corrosion in the air space above the ballast water surface. Also, this will reduce the free surface effect and damage to structures due to sloshing.

16 Points to Consider While Taking in Clean Ballast